MVR

MVR

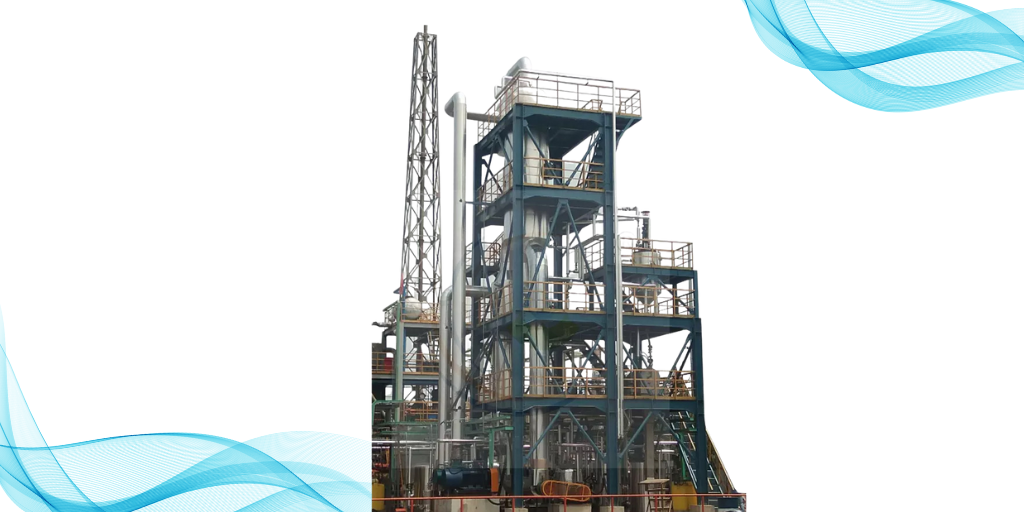

Thermal separation process i.e. Evaporation have been indispensable to a plethora of industries, particularly to chemical, Pharmaceuticals, Agrochemicals, Speciality Chemicals, Dyes and Intermediates, food & beverage, salt works, and environmental technology industries etc. Reduction of energy costs being one of the primary considerations led to the adoption of multiple-effect plants, followed by thermal vapor compression and now being replaced or converted to mechanical vapor recompression which is also known as ‘MVR’ for further reduction of energy cost, reduce overall water losses, minimize energy through reduction of fossil fuel consumption and to bring Environmental sustainability by reducing TOE for production.

As the name suggests, mechanical vapor recompression technology involves the use of a mechanical compressor that recompresses the vapor of an MVR evaporator to a higher pressure. Mechanical vapor recompressor functions as a heat pump adding more energy and increase temperature gradient to the vapor.

MVR technology (Mechanical vapour recompression) offers a whole gamut of benefits ranging from reduced specific energy consumption, low operational costs, seamless evaporation of the product owing to low-temperature differences, simplicity of the process, and top-notch partial load behaviour.

Mechanical Vapour Recompressor Working Principle

Mechanical Vapour Compression machines based on the dynamic principle have rotating impeller blades and a diffuser which is located downstream from the impeller. Impeller blades run at high circumferential speeds and the vapour is supplied with energy. Acceleration of the vapour takes place followed by its de-acceleration which is done by the diffuser. This process helps convert high velocity into high pressure. The machine would be called an Centrifugal Turbo Compressor.

The selection of compressor is determined by numerous parameters including operating conditions, the flow rate of the vapor to be compressed and the pressure rise needed.

To heat an evaporation plant, a temperature difference on the heating surface is needed. Simply put, the temperature and pressure of the heating steam must be higher than the pressure and boiling temperature of the product in the system. This temperature difference is achieved through the compression of evaporated vapor from MVR Evaporator in a compressor.

Our Clients